Think big with

GIGA-Line®

Think big with

GIGA-Line®

The GIGA-Line® portfolio now features a range of unique design collections.

Available in rectified formats of 260 × 120 cm, 120 × 120 cm, 120 × 60 cm, 80 × 80 cm and 60 x 60 cm, the XXL tiles from GIGA-Line® impress with their striking designs, modular components and close alignment with market trends.

Collection

Overview

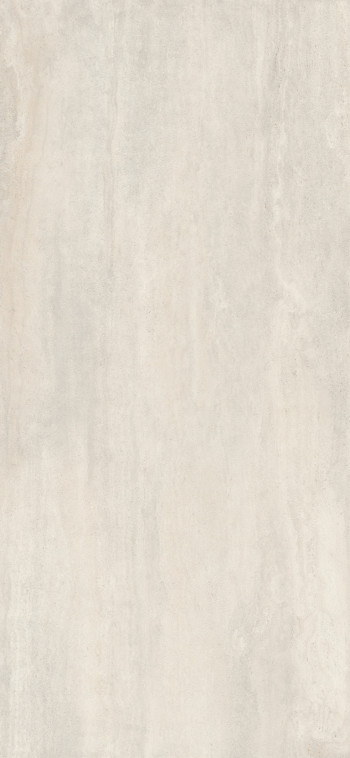

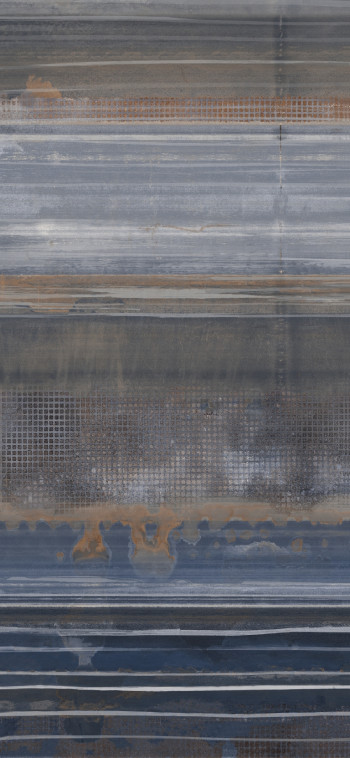

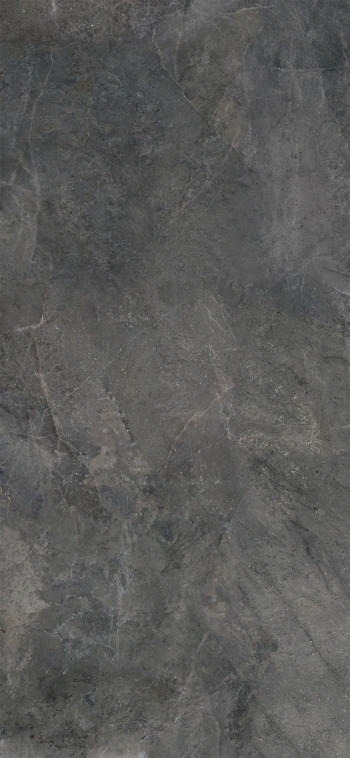

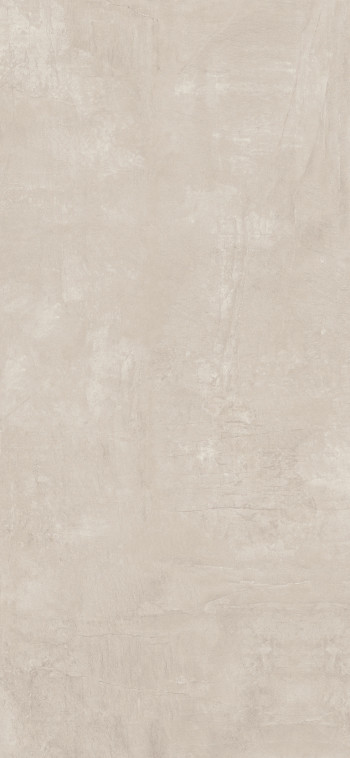

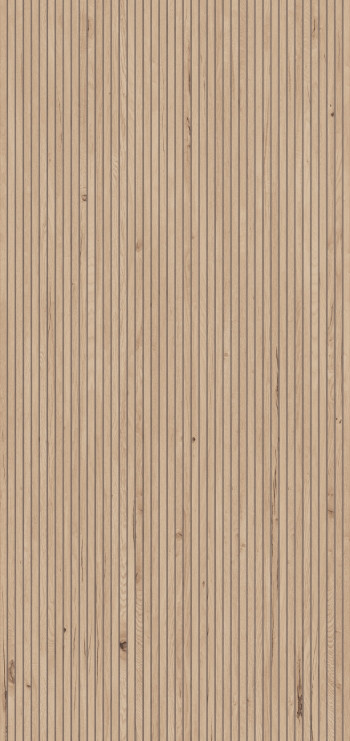

From a minimalist concrete look to striking natural stone effects or the authentic charm of oak – the GIGA-Line® range is as diverse as its areas of application.

You can explore the full range of GIGA-Line® surface designs, as well as the HOME COLLECTION series – equally versatile and perfectly suited for every application – in our Collection Overview.

MADE IN WESTERWALD

Since 2017, Interbau-Blink has been offering state-of-the-art, large-format ceramic tiles under the GIGA-Line® brand, with sizes of up to 260 × 120 cm.

The XXL tiles are produced in the company’s in-house manufacturing facility in Ransbach-Baumbach. The GIGA-Line® plant has enabled the group to enter new markets and expand its product portfolio strategically.

Available in rectified formats of 120 × 260 cm, 120 × 120 cm, 60 × 120 cm, 80 × 80 cm and 60 x 60 cm, the GIGA-Line® series impress with their unique designs, modular components, and close alignment with market needs.

With a thickness ranging from 6 to 20 mm, these slabs are not only suitable for floors and walls but also for applications such as kitchen worktops, stair treads, or fireplace surrounds.

Industry 4.0

From raw material preparation to the kiln, the GIGA-Line® production facility is one of the most advanced tile manufacturing plants in Northern Europe – a true example of Industry 4.0, thanks to its state-of-the-art machinery.

The use of autonomous machines, capable of moving through the production hall and making decisions without human intervention, represents a seamless integration of industrial production with advanced information and communication technology.

The 1.6 m-wide digital printer, the most advanced of its kind, works similarly to an inkjet printer and allows the company, in collaboration with Italian design studios, to create a wide range of designs, including marble, metal, and natural stone effects.

High-Tech Meets Craftsmanship

A large-format tile travels up to half a kilometre along its production journey (see production video here).

Starting with the 440-ton hydraulic press, which compresses the raw material into a flat slab with hundreds of times its own weight, the tile then passes through a 41-metre-long dryer to remove moisture. Next, it receives its final design in the digital printer before being fired in a kiln heated to 1,200°C.

After grinding in the dry-calibration machine and a final quality inspection, the tiles are fully machine-packed and prepared for shipment. With this forward-looking product line, Interbau-Blink continues to uphold the sustainability of its production processes.