Sustainably grounded

in nature itself

Environmental Product Declaration

According to ISO 14025 and EN 15804

The German Ceramic Tile Association (BKF) has had a universally valid Environmental Product Declaration (EPD) prepared for all its members producing in Germany.

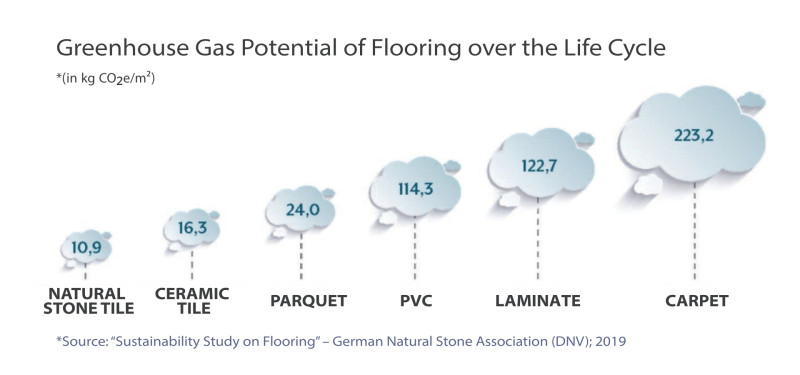

A key aspect of the EPD is the information on greenhouse gas emissions in kg CO2-equivalent per unit produced (for tiles, usually per square meter). In this regard, ceramics perform exceptionally well compared to other flooring materials (2018).

A key aspect of the EPD is the information on greenhouse gas emissions in kg CO2-equivalent per unit produced (for tiles, usually per square meter).

According to a 2018 study (source) by the University of Stuttgart on behalf of the German Natural Stone Association (Deutscher Naturstein-Verband e. V.), ceramics performed exceptionally well compared to other flooring materials.

The value reported in that study—an average of 16.3 kg CO2/m² in 2018—was significantly reduced in the updated 2022 EPD for ceramic tiles produced in Germany, now just 10.2 kg CO2/m²!

These improvements are the result of modernization measures, replacement of old plant technology, and the implementation of various energy-saving initiatives, such as reducing material thickness, optimizing mass offsets and firing processes, lowering kiln temperatures, installing heat recovery systems, and more.

The values cited in the BKF association EPD are based on an average material usage of approximately 18 kg/m². Tiles produced in our Giga-Line® series, with a thickness of only 6 mm, use just 15 kg/m², further reducing CO2 emissions per square meter. Combined with the proximity to our raw material suppliers and our central location within our main market in Germany, short transport distances further minimize CO2 emissions.

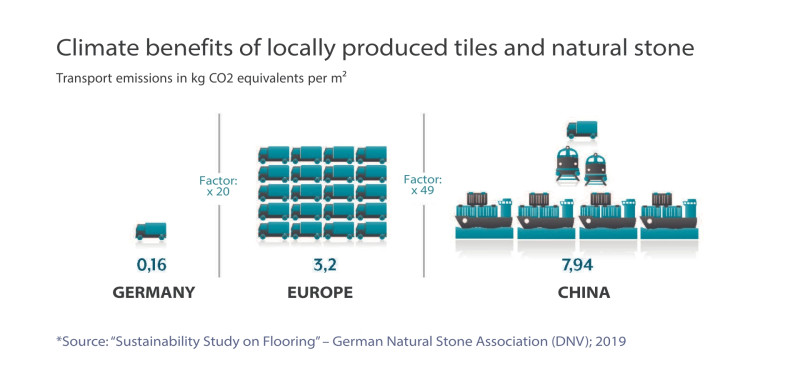

Logistics for tile delivery play a crucial role in the CO2 footprint, especially for overseas imports due to the relatively heavy weight of the products. This is another significant sustainability advantage for locally produced tiles.

Interbau-Blink Tiles:

Made to Stand Out

Ceramic tiles are extremely durable, highly hygienic and easy to clean, making them a particularly resource-efficient product.

Interbau-Blink tiles contain over 70% clay. This primary raw material is mined in close proximity to our production site, while additives such as feldspar also come from the region. Using these natural raw materials and water, a completely natural product is created—100% recyclable.

FAIR MADE

FAIR TRADE

Interbau-Blink produces 100% in Germany, using raw materials from our region. The close proximity to local raw material sources and our location near the German A3 motorway provide optimal conditions for the sustainable production of our products.

As an energy-intensive manufacturer, we take responsibility for our environment and future generations. This is why we place great importance on a resource-efficient production and the careful use of raw materials and energy.

-

Production according to the highest German standards

-

Finest Westerwald clays

-

Certified raw material suppliers

-

Energy management according to ISO 50001

-

Closed raw material cycle

Sustainable

Material Cycle

Taking responsibility for our environment and future generations, we place great importance on the sustainability of our products and the efficient use of raw materials and energy.

Starting with a closed raw material cycle and an efficient recycling system, including on-site wastewater treatment and reuse, utilization of waste heat, and purification of exhaust gases, we employ the latest methods for environmentally friendly production. Only green electricity from renewable energy sources is used in the sustainable manufacture of our tiles.

Sustainability

MANAGEMENT

-

Natural product without modified raw materials

-

No use of nanoparticles

-

Heat recovery concept and thermal recycling

-

Complete wastewater recycling

-

Emission purification in combination with energy-efficent kilns

-

Reintroduction of residual materials into the material cycle

Made from finest

Westerwald Clays

Our site, located in the heart of the Kannenbäckerland region, is in close proximity to the clay deposits we use. This minimizes environmental impact from raw material transportation and saves tons of CO2 and fine dust emissions.

Producing near local raw material sources and close to the market forms the basis of an exemplary balance between economy and ecology.

The result is a regional product of the highest quality, made from the finest Westerwald clays. These clays are considered exceptionally high-quality and guarantee the durability and longevity of our products.

The Origin of Our

Raw Materials

Clay has been mined in the region around Kannenbäckerland since the 13th century. Geographically located between Cologne and Frankfurt, this cultural and industrial landscape—with a technological focus on ceramics—contains the largest clay deposits in Europe.

The clay requirement of the Interbau-Blink group corresponds to approximately 2,040 truckloads (11 to 15 trucks including trailers per working day).

Interbau-Blink works exclusively with raw material suppliers certified according to strict German environmental regulations. The renaturation of former clay pits from our suppliers is ensured through substantial reclamation reserves maintained by the extraction companies.

The raw materials for our products come from local deposits, for example from Stephan Schmidt KG in Dornburg, Germany.

Environmentally harmful “raw material tourism” is avoided. All deposits must be fully renatured under strict regulatory supervision. Compliance with strict reclamation requirements by our raw material partners is closely monitored. Where clay pits once existed, biotopes have now been created.

You can read more about this topic in the environmental statement of our supplier, Stephan Schmidt KG, which participates in the joint system for environmental management and environmental audits (EMAS).

An annual surveillance audit is conducted for our energy management system in accordance with the globally recognized standard of the International Organization for Standardization (ISO). The current certificate for our production facility can be found at the end of this page.

DIN EN ISO 50001, in effect since December 2011, is designed to support the establishment of a systematic energy management system within a company. Our company has once again been certified for maintaining a fully functioning management system that continuously improves energy efficiency and is actively implemented.

The standard aims to identify long-term untapped energy efficiency potential, reduce energy costs, and minimize the environmental impact of energy consumption. During the annual management review, energy targets were reaffirmed, and ambitious energy-saving measures were decided. This demonstrates our company’s continued commitment to people and the environment.

For decades, we have been relying on the independent research institute for inorganic materials (Forschungsinstitut für Anorganische Werkstoffe -Glas/Keramik- GmbH) – in Höhr-Grenzhausen, accredited by the German Accreditation Body (DAkkS No. D-PL-18634-01-00), for our quality testing.

Further

information